Many products surrounding us increasingly utilize adhesive technology, making it one of the inevitable

processing technologies.Whenever there is adhesive sheet, there is needs for "release paper and

release liner".Release liner, the sheet to be removed, protects the adhesive surface until its actual

usage. Besides, it is critical that the released liner can be stripped-off properly at the usage time. We

have been manufacturing various types of release paper and release liner that is necessary for

adhesive technology.

Adhesive sheet may sound simple at first; but its application is quite extensive, with many types

available for different purposes.That is why the demand for release liner is not limited to easy

release.To meet customers' needs for different release liner perfomance, we have been utilizing a

wide ranges of substrates materials.

The advantage of Fujiko gravure coating

- POINT 1

-

Dividing into silicone type and its curing method

Altering between 3 coating methods for "Solvent heat curing", " Solvent UV curing" & "Solventless UV curing" allows us to produce release liners of different performance,and also enables coating for substrate material traditionally hard to use due to its low heat-resistance nature.

- POINT 2

-

Visible release liner through pigment printing

The combination use of coating and gravure printing has enabled us to produce pigmented release paper & release film.In addition, using custom ised printing plate allows us to offer production for industrial designed products.

- POINT 3

-

Manufacturing Anti-static release liner etc.

Combining anti-static & anchor coating material with silicone coating has enabled us to produce release paper and release liner with many added function.

- POINT 4

-

Internal slitting and lamination process,

With coating, slitting and lamination processes intergrated in our internal production, we can handle short lead time production.

- POINT 5

-

Highly clean film

Equipped with clean coating & slitter machine, we can produce release film of high cleanliness. (Some products are excluded)

| 【Examples of available material】 | |

|---|---|

| Polyester | Industrial PET (transparent/milky white), foamed PET |

| Polypropylene | OPP・CPP |

| Polyethylene | LDPE (milky white/transparent), HDPE (milky white/transparent), etc. |

| Other types of plastic films |

There are film that silicone is unable to be cured on. For special film request, we will test to decide if silicone coating is possible. |

| Paper | High quality paper, thin paper, glassine paper, semi-glassine paper, etc. |

【Products list】

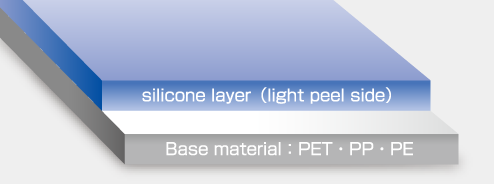

- <General release liner>

The m ost b asic a nd c ommon

composition: coated silicone on

either s ingle or b oth s ides of

various substrate materials.

The m ost b asic a nd c ommon

composition: coated silicone on

either s ingle or b oth s ides of

various substrate materials.- More detail

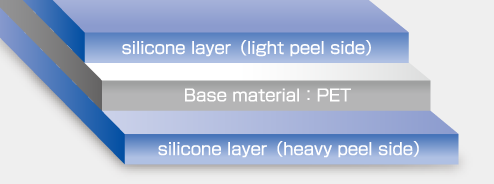

- <Differential release liners - double-sided>

Made by coating silicone on both

sides of various substrate materials.

Creating different release force on

each side makes both sides useable

with tacky adhesive sheet etc.

Made by coating silicone on both

sides of various substrate materials.

Creating different release force on

each side makes both sides useable

with tacky adhesive sheet etc.- More detail

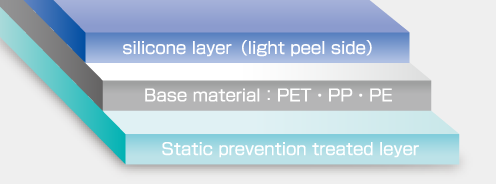

- <Anti-static treated release liner>

Anti-static coat: either at the back

of base material, or at t he layer

below the release treatment layer.

Anti-static coat: either at the back

of base material, or at t he layer

below the release treatment layer.- More detail

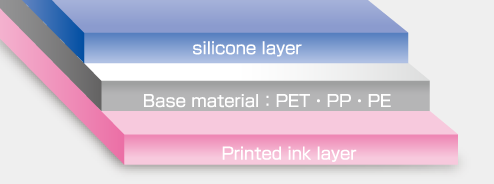

- <Color release liner>

Color printed by gravure printing

on the back side of base material,

or b elow t he r elease c oating

layer, or between 2 base material

layers.

Color printed by gravure printing

on the back side of base material,

or b elow t he r elease c oating

layer, or between 2 base material

layers.- More detail

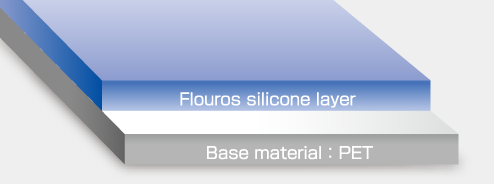

- <Flouros silicone release liner>

Fluoros s ilicone c oated o n P ET b ase

material.Make it possible to produce release

liner with very easy release, even for silicone

adhesive t hat usually damages t he

releasability of common silicone release liner.

Fluoros s ilicone c oated o n P ET b ase

material.Make it possible to produce release

liner with very easy release, even for silicone

adhesive t hat usually damages t he

releasability of common silicone release liner.- More detail

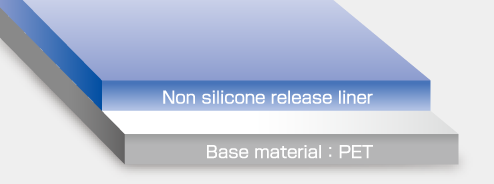

- <Non-silicone release liner>

Designed for p roduct s that

silicone use is not feasible due to

it s u sage p urpose ( silicone

transfer is unacceptable)

Designed for p roduct s that

silicone use is not feasible due to

it s u sage p urpose ( silicone

transfer is unacceptable)- More detail

- <Overview of manufacturing equipment>

In developing and manufacturing release

liner, "cleanliness" is inevitably critical.At

Fujiko, to always provide product of high

cleanliness, we have been raising factory

standards b y eq uipping h igh-tech

manufacturing facility,testing equipment

as well as our staff skills etc.

In developing and manufacturing release

liner, "cleanliness" is inevitably critical.At

Fujiko, to always provide product of high

cleanliness, we have been raising factory

standards b y eq uipping h igh-tech

manufacturing facility,testing equipment

as well as our staff skills etc.- More detail