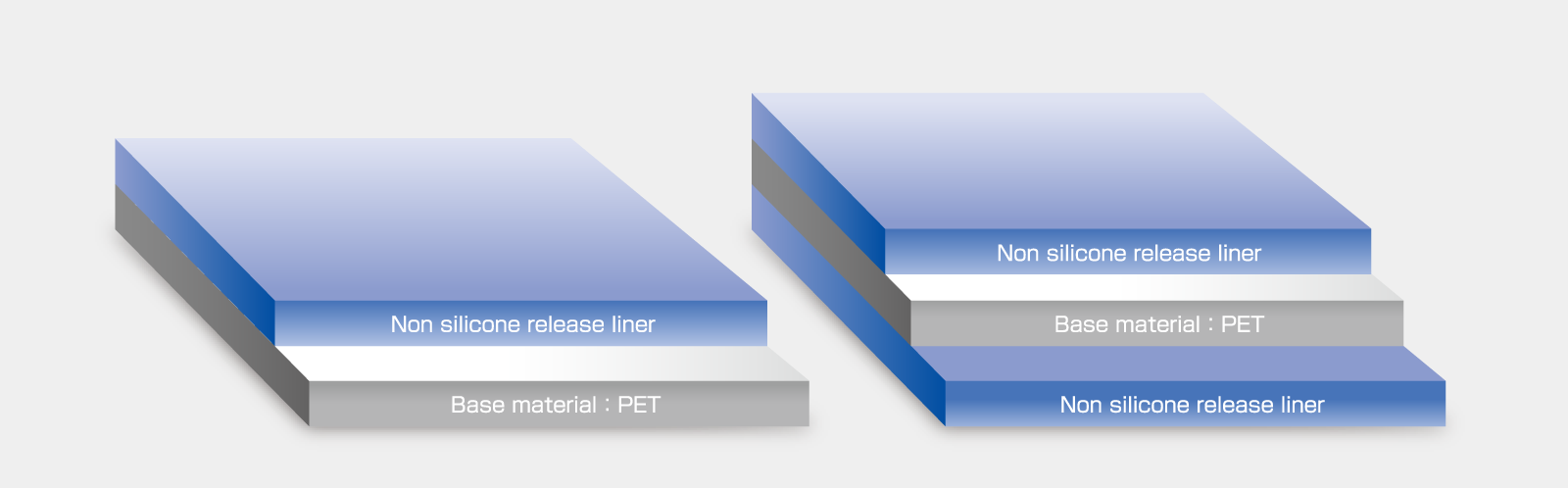

<Non-silicone release liner>

Designed for products that silicone use is not feasible due to its usage purpose (silicone transfer is unacceptable)

- POINT 1

- Guarantee the releaseability even for silicone adhesive and resin.

- POINT 2

- High surface wettability, easy for coating medical materials.

- POINT 3

- For application with release force considered too light (too easy) when done in silicone.

- POINT 4

- Excellent at friction-resistance, solvent-resistance, heat-resistance, it is applicable to various specs.

Apart from the listed specs, we also offer R&D collaboration for customized specs to suit your needs.

【Products list】

| Brand | Attribute | Peel strength (mN/25mm) |

Angle of contact (degree) |

Properties |

|---|---|---|---|---|

| HP-R1 | Non silicone | 150 | 98 | |

| HP-N1 | 800 | 92 | ||

| HP-A0 | 200 | 107 | ||

| HP-A | 3000 | 95 | ||

| HP-A3 | 5000 | 88 | ||

| HP-A5 | 7000 | 81 | ||

| HP-TY1R | 3000 | 93 | ||

| HP-TY3R | 4000 | 90 | ||

| HP-TY5R | 6000 | 88 | ||

| HP-F1 | 10000 | 95 | ||

| HP-S0 / HP-S0A | Low silicone | 100 | 105 | |

| HP-S1 | 1000 | 100 |

[ Peel strength measuring method ]

Nitto tape No.31B 0.3m/min 180 degrees peel. Peel strength after left at room temperature for 20 hours (tape peel).

* The values in the table are not guaranteed values but representative values.

* The values in the table are measured with 75μm liners.

| Application example |

|---|

|