At our company, gravure coating technology gives paper and film various additional function.Amongst

those function, we have developed our own hydrophobic/oleophobic technology where paper and

non-woven materials are given water or oil repellent function t hat does not hinder its air

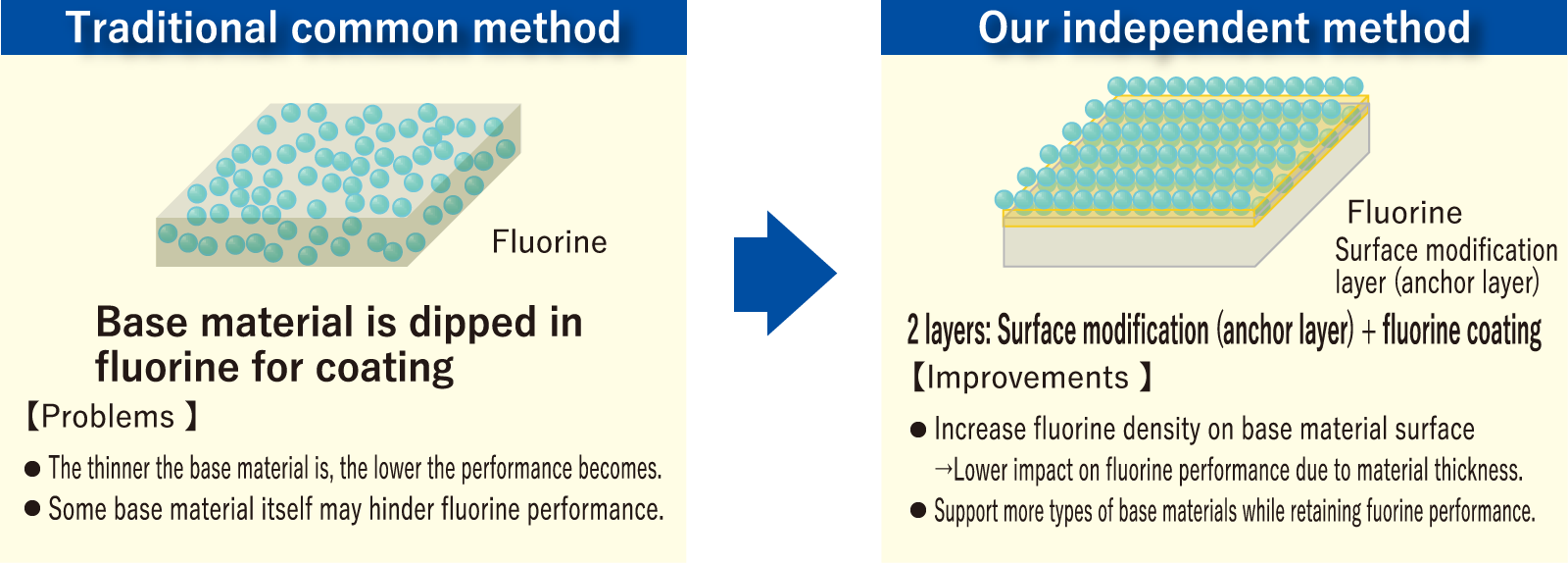

permeability.Our independent manufacturing method has many advantages as it not only brings

water-repellency and oil-repellency function to materials while keeping the processing simple and

easy; but also supports wide ranges of substrate materials.Product safety is certainly prioritized.

Fujiko also offers customized performance for hydrophobic/oleophobic paper to meet customers

actual needs.

Advantage of Fujiko hydrophobic/ oleophobic processing method

- POINT 1

- Utilize eco-friendly flouride type that does not contain PFOA.

- POINT 2

- Adhere to Safety standards by former Ministry of Labour Decree No.370

- POINT 3

- Possible for process used to be considered problematic by conventional production method for common paper.

- POINT 4

- Allows better performace for substrate materials used to be considered hard to retain original performance by conventional method.(Cation type material, rosin sizing agent, substrate materials used aluminium sulfate, synthetic paper, systhetic resin membrane etc.)

- POINT 5

- The fluorine effect on the back layer is kept at the lowest, making it well-suited for secondary process like lamination etc.

- POINT 6

- Better water-repellency and oil-repellency function while retaining material air permeability.

| 【Product perfomance】 | ||||||

|---|---|---|---|---|---|---|

| Unit | Japanese paper (45g/m²) |

Synthetic paper (45g/m²) |

Machine-made paper (40g/m²) |

Tyvek® (45g/m²) |

PE non-woven material (72g/m²) |

|

| Oil repellency | 3Mkit | ≦ 12 | ≦ 11 | ≦ 16 | ≦ 15 | ≦ 14 |

| Water repellency | R | ≦ 10 | ≦ 10 | ≦ 10 | ≦ 10 | ≦ 10 |

| Application example |

|---|

|